This series has been updated. Please click this link to check the new product details page.

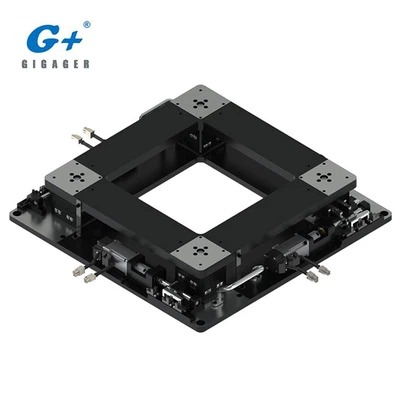

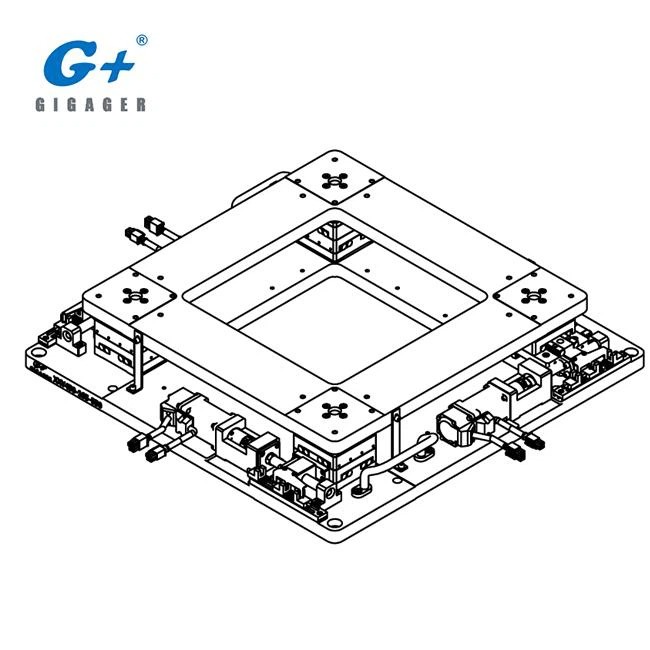

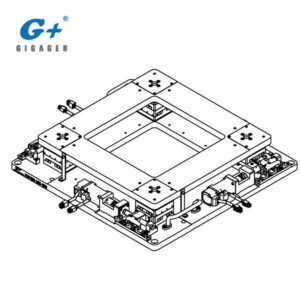

GIGAGER Motorized Alignment Stage XXY450-105-550, also called XXY Alignment Stage or UVW Stage. Available in 10 models, in three precision grades from G level 2μm, B level 5μm, P level 10μm respectively, these model have linear travels±5 mm. Additionally, XXY stages can rotate around the center of the XY plane up to ±5 degree to ±2 degree, while the horizontal loading from 10kg to 100kg.

1. Specification of Motorized Alignment Stage XXY450-105-550

|

Work Table |

450×450 |

Accuracy Level |

G:2μm |

|

Base Size |

550×550 |

B:5μm | |

|

Height |

105 |

P:10μm | |

|

Linear Stroke |

±5 |

N/H: 20μm | |

|

Action Angle |

±1.6° |

Driver Screw |

1202 |

|

Action Flatness |

±0.03 |

Suggesting Load |

Horizontal ≤100KG |

|

Driver |

Servo Motor 100W |

Surface Processing |

Anodizing Sandblasting Treatment |

2. What is the XXY Motorized Alignment Stage?

3. What is the Product Features of GIGAGER XXY Motorized Alignment Stage?

4. Motion Mode of GIGAGER XXY Motorized Alignment Stage

*A,B,C is Rotary axis,D is Slave axis

5. How Many Model Are Available?

6. What Type of Device Could Use the XXY Motorized Alignment Stage?

|

|

|

|

Electronic Inspection Device |

Multi Axis CNC Equipment |

|

|

|

|

Laminating Machine |

Manipulator |

|

|

|

| Laser Processing Device | Polishing Machine |

Video Link: https://youtu.be/N5LYWt6WYIU

For more application, please click GIGAGER Youtube Channel: https://www.youtube.com/playlist?list=PLT-2VrhPP3YItwfN_wA4YkS8bzfBpJu39

7. How to Select the Right Model for My Device?

Please contact with our engineer for model selection suggestion.

8. How to Install the XXY Motorized Alignment Stage?

9. Why choose GIGAGER?

10. FAQ

11. Related Knowledge

The LCD alignment is to automatically identify and position the upper substrate and the lower substrate of the liquid crystal screen according to the alignment mark, and pressurize the UV substrate to cure the previously applied UV resin by UV irradiation. The supply and output of the glass substrate are performed by an in-line type conveying device. The alignment portion is to identify the alignment mark MARK of the upper and lower substrates by the camera, send the data to the image processing for calculation, and then manipulate the XYθ table to perform alignment and press-fitting, and harden the UV resin by the UV irradiation unit. The image recognition technology has been fully analyzed. The image recognition system of the automatic alignment bonding machine has been designed to identify and align the upper and lower glass together with the PLC, X, Y and θ precision motion platforms. High precision alignment of the platform. Practice has proved that the use of image recognition system technology ensures the high precision requirements of equipment alignment and greatly improves the efficiency of equipment operation.

GIGAGER UVW Stage features:

1,Alignment drive of X, Y and Θ axes on the same plane

2. Space-saving design with low height

3. High precision positioning

Welcome to inquire!

Hot Tags: motorized alignment stage, China, manufacturers, suppliers, factory, high quality, high quality wafer alignment stage, high quality motorized positioning stages, high quality alignment positioning table, xy theta alignment stage, alignment positioning table, xxy plane robot